From Founding to Market Leadership

The Beginning in Korea

GEIOS Technologies was founded in Korea, marking the start of our journey to revolutionize geothermal energy through breakthrough subsurface engineering and nanotechnology.

Nanogeios Lab & SPARC Innovation

Established Nanogeios Laboratory and began developing SPARC Nanofoam technology. Our proprietary nanomaterials started taking shape, designed to withstand extreme subsurface conditions.

Testing & Simulations

Intensive laboratory testing and simulations validated our breakthrough technologies. SPARC Nanofoam achieved 12.7× thermal conductivity enhancement with zero seismicity—materials engineered to survive extreme conditions.

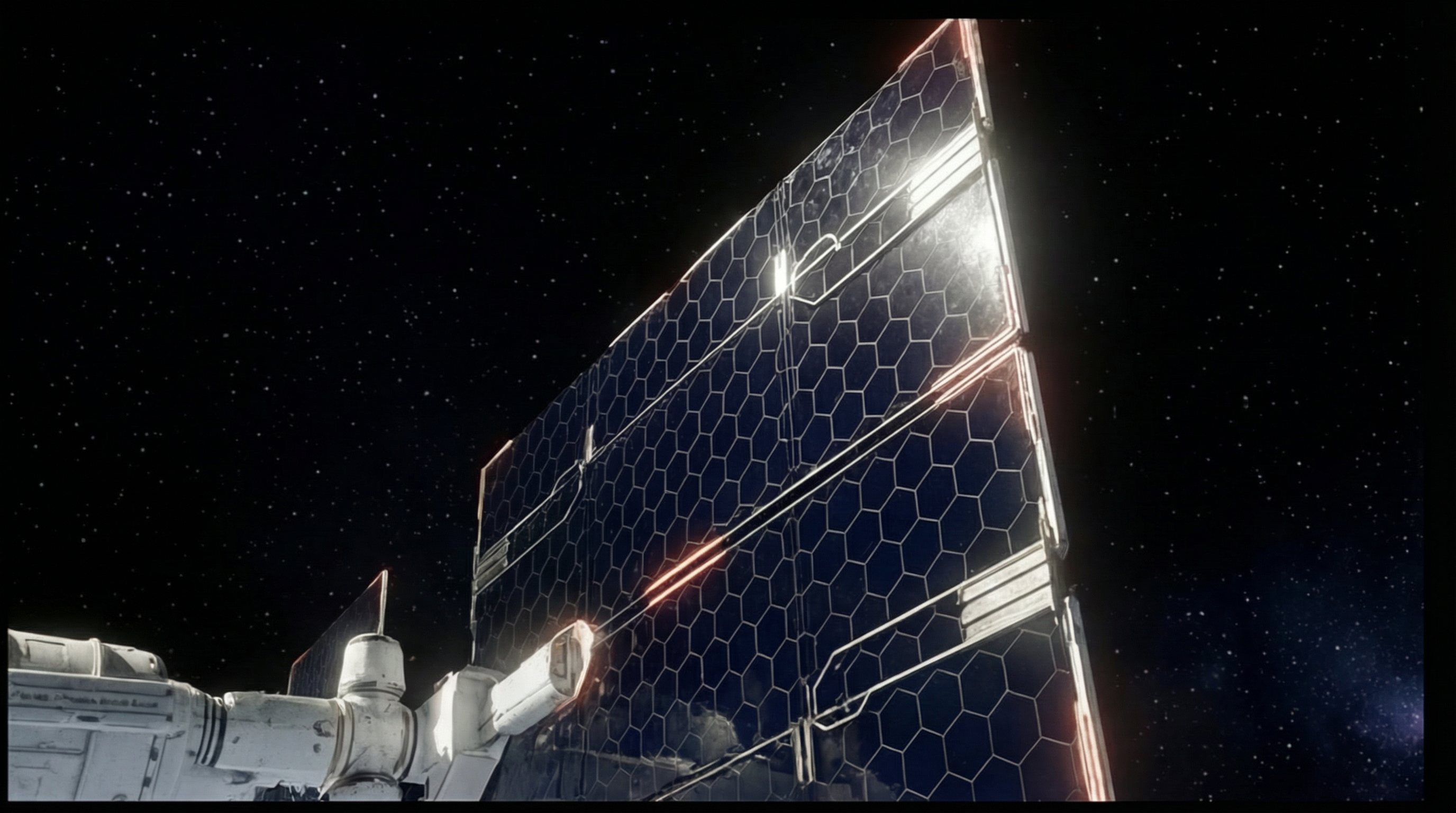

The Fusion Insight

Geothermal became our proving ground for universal nanotech applications. The extreme conditions (heat, corrosion, pressure) unlocked modular solutions for every industry—from oil recovery to aerospace fuels.

Market-Ready Technology

After extensive testing and lab validation, our technology is ready for market deployment. With $9M+ revenue generated through Nanogeios Laboratory, we've entirely self-financed our R&D—proving innovation can fund itself.